Describe the Casting Process in Detail Using the Appropriate Terminology

Centrifuge Casting - A casting technique. The mold in investment casting is produced by coating a wax pattern.

Handbook The Ultimate Guide To Metal Casting Metal Casting It Cast Metal Casting Molds

Molten metal is poured into a mold.

. The most common process uses gravity to fill the mold. It is the first step in manufacturing most products. Sand casting also known as sand molded casting is a metal casting process characterized by using sand as the mold material.

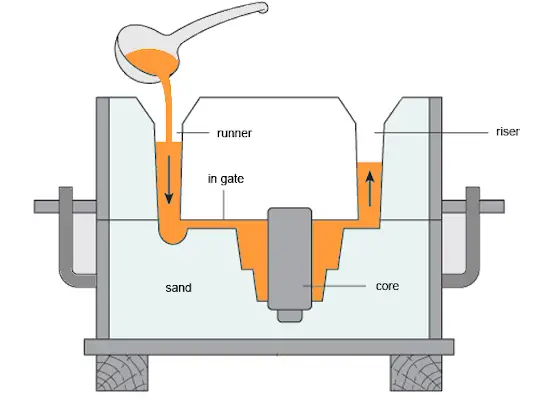

Casting process and sand casting terminology 1. The surface of the casting material can be agitated to help it flow. Describe the principles of metal casting process.

See also Centrifuge Casting. Molten metal is moved from the center to the periphery by centrifugal action. This process uses no cores and the symmetrical hollow section is created by pure centrifugal action.

Why is the investment-casting process capable of producing fine surface detail on castings. It is the physical model of the casting used to make the mould. Cold shut misrun slag inclusion.

The six basic steps in making sand castings are i Pattern making ii Core making iii Moulding iv Melting and pouring v Cleaning Pattern making - Pattern. The pattern itself can have extremely good detail and surface finish as it can be produced by die casting or even machining or rapid prototyping and finishing operations. The art of making objects of clay and firing them in a kiln.

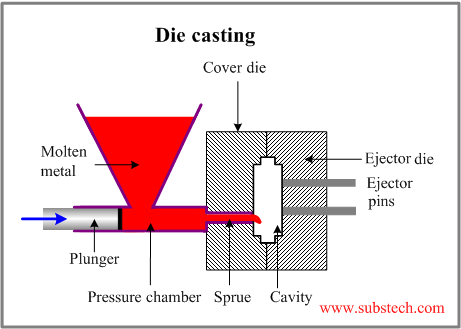

High Pressure Die Casting. Describe the main functions of the mold used in the metal casting process. 6424 Pour the casting material from outside the perimeter and direct the flow into the impression.

Sand casting the most widely used casting process utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Casting offers exceptional freedom in. Types of castings sand casting and die casting.

This process is widely used to manufacture complex parts which cannot be made by other processes. Because the sand mold must be destroyed in order to remove the part called the casting sand casting typically has a low production rate. Permanent mold casting is a metal casting process that employs reusable molds permanent molds usually made from metal.

Bottom board Pattern Molding sand Backing sandFacing sand Flask Parting line Core and chaplet Chill Pouring basin Sprue RunnerGate Riser. Commonly the term casting also applies to the part made in the process. Once in the mold the metal cools and solidifies in the shape of the mold cavity.

The defect caused due to misalignment of upper and lower part of the casting and misplacement of the core at parting line. Product Development Second Edition 2014. Sand castings are produced in specialized factories called foundries.

True centrifugal casting is sometime known as centrifugal casting is a process of making symmetrical round hollow sections. Shrinkage Contraction of metal in the mold during solidification. Replica of the part to be cast and is used to prepare the mould cavity.

Examples of molds cake-pan an ice-cube-tray or the. Or 2 pouring metal into a mold that is subsequently revolved before solidification of the metal is complete. Hot tears hot spot.

Made of either wood or metal. The term also is used to describe the casting defect such as shrinkage cavity which results from poor design insufficient metal feed or inadequate feeding. Describe the main functions of the mold used in the metal casting process.

The term sand casting can also refer to an object produced via the sand casting process. The process of making a sculpture or other object by pouring liquid material such as clay metal or plastic into a mold and allowing it to harden thereby taking on the shape of the confining mold. Mold cavity is produced having the desired shape and size of the part Takes shrinkage into account Single-use or permanent mold 2.

6423 Add the appropriate amount of water to the pre- measured dental stone. Casting is a manufacturing process in which a liquid material is usually poured into a mold which contains a hollow cavity of the desired shape and then allowed to solidify. In this process the mould rotates about horizontal or vertical axis.

Casting terms and definitions Casting. CASTING PROCESSS Casting is a manufacturing process by which a liquid material is usually poured into a mold which contains a hollow cavity of the. A thicker mixture should be used for snow.

Describe the principles of metal casting process. Manufacturing process used to produce solid metal pieces called castings. CASTING PROCESS TERMINIOLOGY USED IN SAND CASTING PROCESS 2.

Terms Used In Casting Process. The metal casting process is the oldest and popular method of manufacturing means of designing the desired shapes. Shakeout The process of separating the solidified casting from the mold material.

Casting is made from any metal that can be melted and can have any shape the designer desires. Melting process Provides molten material at the proper temperature 3. CENTRIFUGAL CASTING Process of filling moulds by pouring the metal into sand or metal mould revolving about either its horizontal or vertical axis and continues pouring the metal into the mould that is being revolved before solidification of metal is complete.

The various casting defects that appear in the casting process are. The term casting is commonly used for metalsThe term molding is used for plastics. The solidified part is also known as a casting which is ejected or broken out of the mold to complete the process.

643 Casting with sulfur. A process of filling molds by 1 pouring metal into a sand or permanent mold that is revolving about either its horizontal or its vertical axis. TABLES OF CONTENTS History Definition of casting 3.

The sand casting process involves the use of a furnace metal pattern and. The process can be applied on metals ceramics and plastics. However gas pressure or a vacuum are also used.

The casting process basically is accomplished by pouring a liquid material into a mold cavity of the shape of the desired part and allowing it to cool. A variation on the typical gravity casting process called slush casting produces hollow castings. Basic Requirements of Casting Processes Six basic steps of casting 1.

The castings can produce in sizes ranging from a few mm to several meters. Casting is defined as a manufacturing process in which molten metal pure into a mold or a cavity of desire shape and allow to solidify which form a predefine shape.

What Is Casting Definition Types Of Casting Engineering Choice

What Is Casting Defects Types Causes And Remedies Mechanical Booster

What Is Casting Definition Types Of Casting Engineering Choice

Wow Verb Examples Digital Storytelling Tech Integration

What Is Core In Casting 5 Types Of Cores You Should Know

Types Of Pattern In Casting Process Explained In Detail Pdf

Types Of Pattern In Casting Process Explained In Detail Pdf

Typhoon Touch Microprocessor Tsutsumi Language Functions Touch Appropriate

Sand Casting Is The Oldest Casting Process That Exists It Uses Pattern Made Of Either Metal Wood Or Wax To Create Sand Casting It Cast Metal Casting Process

Nice Writing Your Qualifications In Cnc Machinist Resume A Must Check More At Http Snefci Org Writing Qualifications Cnc Machinist Resume Must

Different Types Of Casting Processes Used In Manufacturing

Wtf Is A Gender She They On Instagram Good Terms To Know Instagram Gender Cute Anime Character

Investment Casting Process Compounds Science Investing It Cast

The Difference Between Screen Mirroring Screen Casting Screen Mirroring It Cast Mirror

Comments

Post a Comment